PHQ (light) model suits to brittle materials of mohs hardness grade 2, including coal, gangue, coke, slag, shale and etc..

PHZ (heavy) model is for different kinds of rocks of mohs hardness grade 5 and below, including limestone, magnetic iron ore, phosphorous ore and etc..

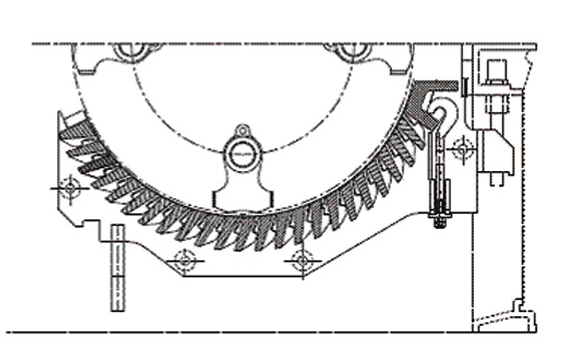

The ring hammer can not only rotate with rotor but also self-rotate around hammer axis pin. After being fed into the crusher, the material are impacted and broken in the cavity by ring hammers rotating at high speed with rotor. With kinetic energy from ring hammer, the broken material are thrown into breaker plates and crushed for the second time while failing on the screen plates. The material are further crushed with shearing, squeezing and grinding by ring hammers and intra-collision, and finally are discharged out of the crusher through screen holes. The unbreakable impurities are pushed into metal collector to be cleaned up by operators. Product size is adjusted by replacing different models of screen plates. The gap between rotor and screen plates can be modified through a regulator mechanism.

-

Drive unit

The rotor is driven directly by the motor through fluid coupling or elastic pin coupling.

-

Rotor

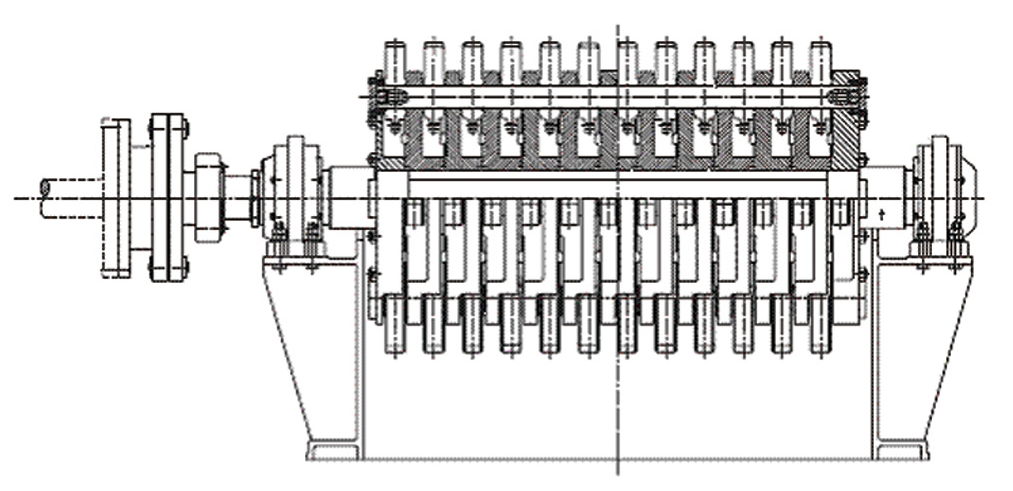

The rotor is assembled with main shaft, end plates, division plates, hammer pins and ring hammers. Ring hammer is hung over hammer pin fitted between end plates and division plates, which are fixed on main shaft with parallel keys and nuts.

-

Housing body

The housing body is made of housing, breaker plates, screen plates, impact plates, liners and support plates. Breaker plates and screen plates are installed on support plates, of which one end is fixed on upper housing with a shaft; another end is connected with regulator mechanism through connection plates. Liners are fitted on two sides of inner wall in the housing to protect it from wearing. Breaker plates, screen plates, impact plates and rotor form the breaking cavity. The housing can be opened up at two sides by a hydraulic power pack for easy maintenance.

-

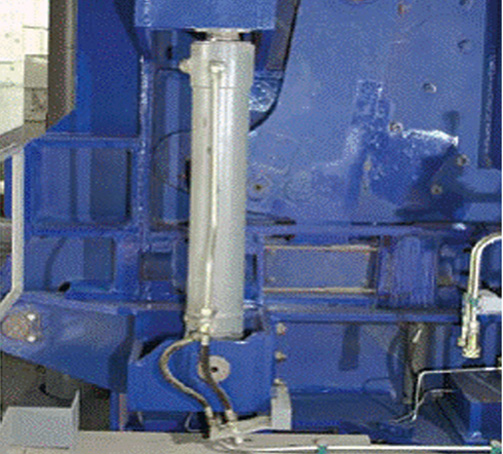

Regulator mechanism

Regulator mechanism, consisting of worm, gear and gap indicator, is used to modify and indicate the gap between rotor and screen plates.

Shock-absorption platform is equipped to reduce vibration and noise.

Bearing temperature and vibration monitor box are provided on site with signals transmitted to main control room.

Combined with fluidized bed drying system, the ting granulator can adjust moisture content of material while crushing selectively.

Ring granulator mainly consists of drive unit, rotor, housing body, regulator mechanism and etc..

|

Model No. |

Output(t/h) |

Feed size(mm) |

Product size(mm) |

Motor power(kw) |

|

PHQ/Z1108 |

200 |

≤250 |

≤25 |

132 |

|

PHQ/Z1111 |

300 |

≤250 |

≤25 |

185 |

|

PHQ/Z1114 |

400 |

≤250 |

≤25 |

250 |

|

PHQ/Z1117 |

500 |

≤250 |

≤25 |

315 |

|

PHQ/Z1218 |

600 |

≤300 |

≤25 |

355 |

|

PHQ/Z1221 |

800 |

≤300 |

≤25 |

450 |

|

PHQ/Z1226 |

1000 |

≤300 |

≤25 |

560 |

|

PHQ/Z1229 |

1200 |

≤300 |

≤25 |

630 |

|

PHQ/Z1825 |

1400 |

≤400 |

≤25 |

710 |

|

PHQ/Z1828 |

1700 |

≤400 |

≤25 |

1100 |

|

PHQ/Z1831 |

2000 |

≤400 |

≤25 |

1200 |

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube