ANDE metallurgical provides high quality crushing and pelletizing equipment and system solutions for global customers

-

Pulverized coal injection (PCI) for furnace & kilnANDE has about 150 employees, total of them about 40 with middle and senior professional titles, majored in metallurgy, mining, mechanical engineering design, mechanical process, welding, electrical, instrumentation, automation control and etc. It has strong research and design ability in metallurgy & mining equipment and system.

Pulverized coal injection (PCI) for furnace & kilnANDE has about 150 employees, total of them about 40 with middle and senior professional titles, majored in metallurgy, mining, mechanical engineering design, mechanical process, welding, electrical, instrumentation, automation control and etc. It has strong research and design ability in metallurgy & mining equipment and system. -

GrindingTaking the vertical roller mill as the core, a short flow primary powder collection process is adopted, which is combined with the feeding system, dust collection system and drying system. It can grind all kinds of medium and low hardness materials (coal, limestone, lime, slag, manganese ore, bentonite, etc.) from millimeter level to micron level.

GrindingTaking the vertical roller mill as the core, a short flow primary powder collection process is adopted, which is combined with the feeding system, dust collection system and drying system. It can grind all kinds of medium and low hardness materials (coal, limestone, lime, slag, manganese ore, bentonite, etc.) from millimeter level to micron level. -

-

-

-

-

Active limeCompared with ordinary lime, the advantages of active lime are: Less volume density (1.5~1.7g/cm3) Larger specific surface area (1.2~2m2/g) Higher porosity (up to 50%) Mineral crystal of calcium oxide is finer (1-3μm) Higher chemical purity (CaO>92%,SiO2+Fe2O3+Al2O3<3%,S<0.02~0.05%) Lower content of residual CO2 (LOI≤2~5%) Higher activity (up to 380ml) Most of premium active lime are being produced with rotary kiln technology in USA,

Active limeCompared with ordinary lime, the advantages of active lime are: Less volume density (1.5~1.7g/cm3) Larger specific surface area (1.2~2m2/g) Higher porosity (up to 50%) Mineral crystal of calcium oxide is finer (1-3μm) Higher chemical purity (CaO>92%,SiO2+Fe2O3+Al2O3<3%,S<0.02~0.05%) Lower content of residual CO2 (LOI≤2~5%) Higher activity (up to 380ml) Most of premium active lime are being produced with rotary kiln technology in USA, -

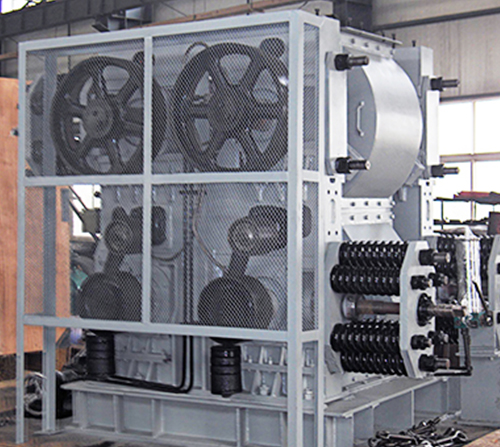

Pelletizing0.3–1.2mtpa Grate–Kiln production line: Plant design Equipment design, manufacturing & installation Project commissioning Training and etc. Complete equipment and design/construction of turn-key grinding plants for coal, cement clinker and blast furnace granulated slag. Up-to-date crushing & sizing equipment and system solution for metallurgy, mining and construction industry.

Pelletizing0.3–1.2mtpa Grate–Kiln production line: Plant design Equipment design, manufacturing & installation Project commissioning Training and etc. Complete equipment and design/construction of turn-key grinding plants for coal, cement clinker and blast furnace granulated slag. Up-to-date crushing & sizing equipment and system solution for metallurgy, mining and construction industry. -

Sintering24-360m2 Sinter–Cooler production line: Plant design Equipment design, fabrication & installation Project commissioning Operation service 0.3–1.2mtpa Grate–Kiln production line: Plant design Equipment design, manufacturing & installation Project commissioning Training and etc. Complete equipment and design/construction of turn-key grinding plants for coal, cement clinker and blast furnace granulated slag. Up

Sintering24-360m2 Sinter–Cooler production line: Plant design Equipment design, fabrication & installation Project commissioning Operation service 0.3–1.2mtpa Grate–Kiln production line: Plant design Equipment design, manufacturing & installation Project commissioning Training and etc. Complete equipment and design/construction of turn-key grinding plants for coal, cement clinker and blast furnace granulated slag. Up -

-

Flue gas purificationMainstream Technologies of FGD for Coal-fired Power Plant Wet method -- limestone/gypsum method, ammonia-ammonium sulfate method, magnesium oxide method, seawater washing method. Semi-dry method: spray drying, electric furnace calcium injection and tail humidification activation method. Dry process -- limestone injection furnace process, electron beam radiation desulfurization and denitrification process.

Flue gas purificationMainstream Technologies of FGD for Coal-fired Power Plant Wet method -- limestone/gypsum method, ammonia-ammonium sulfate method, magnesium oxide method, seawater washing method. Semi-dry method: spray drying, electric furnace calcium injection and tail humidification activation method. Dry process -- limestone injection furnace process, electron beam radiation desulfurization and denitrification process. -

Our advantages are as follows

ANDE has devoted to R & D of new technologies, and has obtained a number of patents and software copyrights, including:

Grinding roller circulating lubrication device (patent No.: ZL 2018 2 0419135.5)

VRM protection device for interrupted feeding (patent No.: ZL 2018 2 0426903.X)

Waste heat recovery technology for active lime rotary kiln line (patent No.: ZL 2020 1 0954122.X) Coal injection control system of lime kiln:(copyright No.: 2018SR382558)

Coal injection system of pelletizing rotary kiln (copyright No.: 2018SR382020)

Automatic control system of fuel and combustion air for HGG (copyright No.: 2018SR380452)

Coal pulverizing & injection control system for BF (copyright No.: 2018SR382323)

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube