Pelletizing

0.3–1.2mtpa Grate–Kiln production line:

Plant design

Equipment design, manufacturing & installation

Project commissioning

Training and etc.

Complete equipment and design/construction of turn-key grinding plants for coal, cement clinker and blast furnace granulated slag.

Up-to-date crushing & sizing equipment and system solution for metallurgy, mining and construction industry.

-

Dust recycling

The return fine and dust will be recycled for reuse. ... -

Environment protection

Multi-tube dust collector. Cyclone. Precipitator. ... -

Coal grinding system

Mid-speed roll mill. High-density bag collector. Short-cut process flow. High... -

Grate – Kiln- Cooler

Drying, heating, baking and cooling processes in individual equipment. Air flow system. ... -

Sieving and distributing

Uniform distribution. High qualification of pellet size. Assure air penetration in ... -

Balling disc

Large-diameter. AC frequency-converter motor. Adjustable inclination angle. L... -

The proportioning system

Automatic control. AC frequency - variable feeding device. ...

-

Balling discΦ6000 balling disc is used for pelletizing of iron ore fines. As one of main support equipment for various pellet plants, the equipment has strong adaptability, its inclination angle and rotation speed are adjustable, and the equipment adopts el...

Balling discΦ6000 balling disc is used for pelletizing of iron ore fines. As one of main support equipment for various pellet plants, the equipment has strong adaptability, its inclination angle and rotation speed are adjustable, and the equipment adopts el... -

Travelling grateThis machine is the dehydration equipment in the production line of oxidized pellet by grate-kiln method. Its function is to dry and dehydrate φ8-φ16mm ellipsoidal ball after rolling process. The working process of travelling grate is: sieve the...

Travelling grateThis machine is the dehydration equipment in the production line of oxidized pellet by grate-kiln method. Its function is to dry and dehydrate φ8-φ16mm ellipsoidal ball after rolling process. The working process of travelling grate is: sieve the... -

Rotary kilnThis rotary kiln is a kind of pellet kiln, the shell of which is made by steel plate rolling and welding. The inner diameter and length of kiln shell is 4.3m and 30m respectively. Inside the shell are lined with refractory bricks. The s...

Rotary kilnThis rotary kiln is a kind of pellet kiln, the shell of which is made by steel plate rolling and welding. The inner diameter and length of kiln shell is 4.3m and 30m respectively. Inside the shell are lined with refractory bricks. The s... -

Annular coolerThis 30㎡ blast pellet annular cooling machine (hereafter referred to as annular cooling machine) is one of the major equipment in the production of metallurgical pellets. It is used in cooling the ~1150℃ pellets discharged from rotary kilns with...

Annular coolerThis 30㎡ blast pellet annular cooling machine (hereafter referred to as annular cooling machine) is one of the major equipment in the production of metallurgical pellets. It is used in cooling the ~1150℃ pellets discharged from rotary kilns with... -

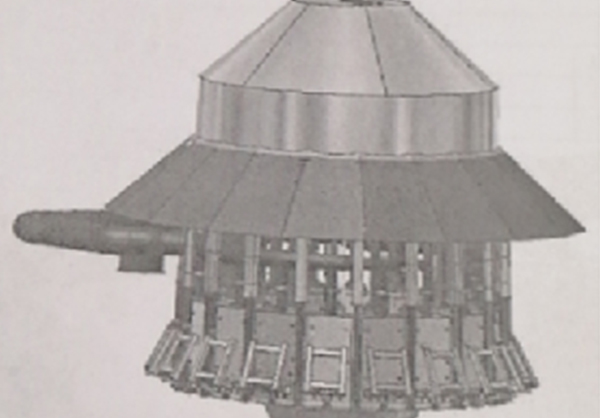

Bell less topAdvantages of AS bell-less top Excellent process performance - Multifunction and accurate distribution can be achieved, such as single ring, multi ring, spiral, section, fixed positing; Simplified structure, reliable operat...

Bell less topAdvantages of AS bell-less top Excellent process performance - Multifunction and accurate distribution can be achieved, such as single ring, multi ring, spiral, section, fixed positing; Simplified structure, reliable operat... -

Vertical preheateMain function of shaft preheater is that qualified limestone is sent to main body of preheater to exchange heat with counter flow high-temperature flue gas (about 1150℃) discharged from rotary kiln after calcination. ...

Vertical preheateMain function of shaft preheater is that qualified limestone is sent to main body of preheater to exchange heat with counter flow high-temperature flue gas (about 1150℃) discharged from rotary kiln after calcination. ... -

Vertical coolerCalcined lime inside rotary kiln enters into the shaft cooler main body through kiln and grate bar device in sequence. Kiln head hood and inner wall of shaft cooler are lined with refractory materials. Cross section of shaft cooler is square. ...

Vertical coolerCalcined lime inside rotary kiln enters into the shaft cooler main body through kiln and grate bar device in sequence. Kiln head hood and inner wall of shaft cooler are lined with refractory materials. Cross section of shaft cooler is square. ...

Our advantages are as follows

ANDE has devoted to R & D of new technologies, and has obtained a number of patents and software copyrights, including:

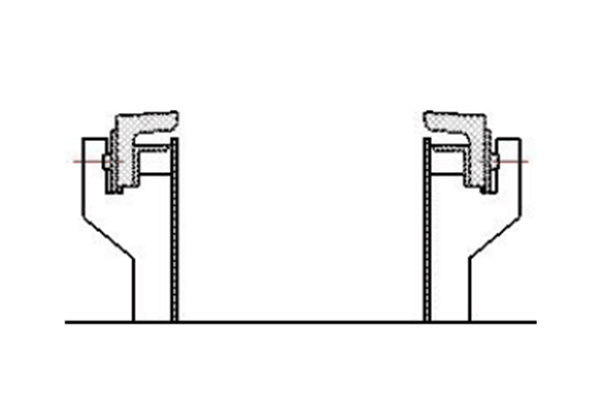

Grinding roller circulating lubrication device (patent No.: ZL 2018 2 0419135.5)

VRM protection device for interrupted feeding (patent No.: ZL 2018 2 0426903.X)

Waste heat recovery technology for active lime rotary kiln line (patent No.: ZL 2020 1 0954122.X) Coal injection control system of lime kiln:(copyright No.: 2018SR382558)

Coal injection system of pelletizing rotary kiln (copyright No.: 2018SR382020)

Automatic control system of fuel and combustion air for HGG (copyright No.: 2018SR380452)

Coal pulverizing & injection control system for BF (copyright No.: 2018SR382323)

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube