Calcined lime inside rotary kiln enters into the shaft cooler main body through kiln and grate bar device in sequence. Kiln head hood and inner wall of shaft cooler are lined with refractory materials. Cross section of shaft cooler is square.

Calcined lime inside rotary kiln enters into the shaft cooler main body through kiln and grate bar device in sequence. Kiln head hood and inner wall of shaft cooler are lined with refractory materials. Cross section of shaft cooler is square.

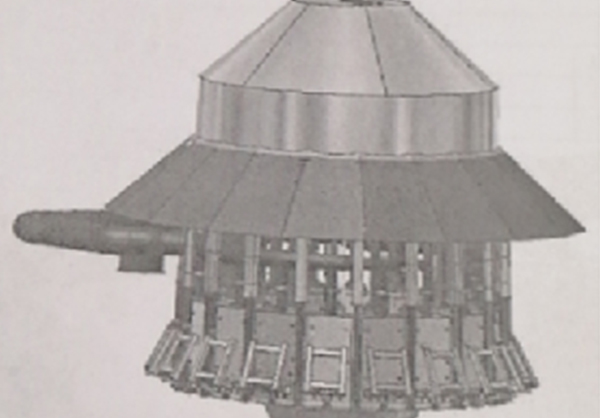

Calcined lime inside rotary kiln enters into the shaft cooler main body through kiln and grate bar device in sequence. Kiln head hood and inner wall of shaft cooler are lined with refractory materials. Cross section of shaft cooler is square. 1 nos. of central air cap and 4 nos. of chamber air caps are arranged at the lower part of shaft cooler. To guarantee uniform air distribution at cross-section, annular cap is installed around chamber caps. Each chamber cap, annular cap and central cap are all equipped with individual pipe connected with external main cooling air piping. 4 nos. of discharge ports are installed at the bottom of shaft cooler, 1 nos. of electric vibration unloader is installed under each discharge port. Lime is accumulated in the cooler main body, and cooling air enters into each air cap through pipe. After escaping from cap, it contacts with high-temperature lime and carries out counter current heat exchange. Lime cooled by air is gradually discharged from the cooler under action of electric vibration unloader. Air heated to 600 ℃ or above directly enters into rotary kiln through kiln head hood, which is used as secondary air for combustion.

Main structure of shaft cooler includes: kiln head hood, kiln head sealing device, grate device, cooler main body, discharge device, support device, large material cleaning device, etc..

|

SN |

Item |

Unit |

Specification |

Remarks |

|

1 |

Manufacturer |

|

ANDE |

|

|

2 |

Model |

|

SL200 |

|

|

3 |

Designed capacity |

t/d |

200 |

|

|

4 |

Dimension |

|

|

|

|

Height |

m |

14.5 |

|

|

|

Length x width |

m |

3×3 |

|

|

|

5 |

Parameters of production process |

|

|

|

|

Feeding temperature |

℃ |

>950 |

|

|

|

Cooling time of lime in shaft cooler |

h |

>1.0 |

|

|

|

Discharge temperature of shaft cooler |

℃ |

Environment temperature+65 |

|

|

|

Inlet temperature of cooling air |

℃ |

Normal temperature |

Atmosphere temperature |

|

|

Exit temperature of cooling air |

℃ |

>600 |

|

|

|

Pressure drop of system |

Pa |

3500 |

|

|

|

6 |

Total weight of equipment |

t |

42.6 |

Excluding refractory |

|

7 |

Total installed motor power |

kW |

6.5 |

|

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube