ANDE provides high quality crushing and sizing equipment and system solutions for global customers

Performance

Technology

-

VRMAs a kind of high efficiency grinding equipment, vertical roller mill is widely used for grinding various materials with high requirements of fineness and energy efficiency. The grindability is from easy grinding to difficult grinding, and ...

VRMAs a kind of high efficiency grinding equipment, vertical roller mill is widely used for grinding various materials with high requirements of fineness and energy efficiency. The grindability is from easy grinding to difficult grinding, and ... -

Ball millAs a kind of high efficiency grinding equipment, vertical roller mill is widely used for grinding various materials with high requirements of fineness and energy efficiency. The grindability is from easy grinding to difficult grinding, and ...

Ball millAs a kind of high efficiency grinding equipment, vertical roller mill is widely used for grinding various materials with high requirements of fineness and energy efficiency. The grindability is from easy grinding to difficult grinding, and ... -

High pressure roller millAs a kind of high efficiency grinding equipment, vertical roller mill is widely used for grinding various materials with high requirements of fineness and energy efficiency. The grindability is from easy grinding to difficult grinding, and ...

High pressure roller millAs a kind of high efficiency grinding equipment, vertical roller mill is widely used for grinding various materials with high requirements of fineness and energy efficiency. The grindability is from easy grinding to difficult grinding, and ... -

Reversible Impact Hammer MillMainly used to crush Coal for circulating fluidized bed boiler Coking coal for coke even Coal, coke, limestone, dolomite, lime and etc. for sinter plant All kinds of low and medium hardness ore, such as iron ore, phosphate rock and etc. ...

Reversible Impact Hammer MillMainly used to crush Coal for circulating fluidized bed boiler Coking coal for coke even Coal, coke, limestone, dolomite, lime and etc. for sinter plant All kinds of low and medium hardness ore, such as iron ore, phosphate rock and etc. ... -

Ring GranulatorPHQ (light) model suits to brittle materials of mohs hardness grade 2, including coal, gangue, coke, slag, shale and etc.. PHZ (heavy) model is for different kinds of rocks of mohs hardness grade 5 and below, including limestone, magnetic iron ore...

Ring GranulatorPHQ (light) model suits to brittle materials of mohs hardness grade 2, including coal, gangue, coke, slag, shale and etc.. PHZ (heavy) model is for different kinds of rocks of mohs hardness grade 5 and below, including limestone, magnetic iron ore... -

Single Roll CrusherSingle roll crusher integrates jaw crusher and roll crusher together, thus has characteristics of the two types of crushers. ...

Single Roll CrusherSingle roll crusher integrates jaw crusher and roll crusher together, thus has characteristics of the two types of crushers. ... -

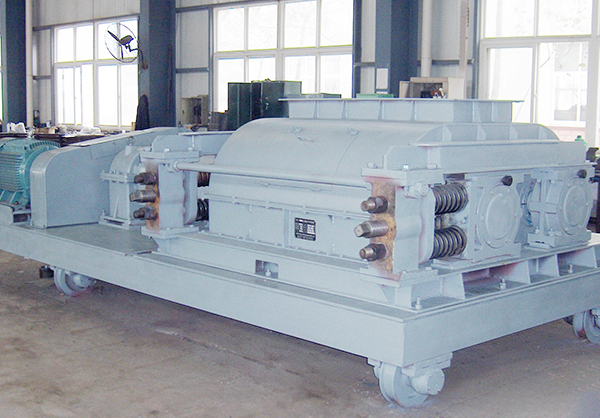

Double Roll / Four Roll CrusherDouble roll crusher is primary crusher for material, reduced from (-)80 mm to (-)25mm, with crushing ratio up to 5:1. Four roll crusher is an integrator of primary and secondary crushing. The size of material can be reduced directly from 40mm to (...

Double Roll / Four Roll CrusherDouble roll crusher is primary crusher for material, reduced from (-)80 mm to (-)25mm, with crushing ratio up to 5:1. Four roll crusher is an integrator of primary and secondary crushing. The size of material can be reduced directly from 40mm to (... -

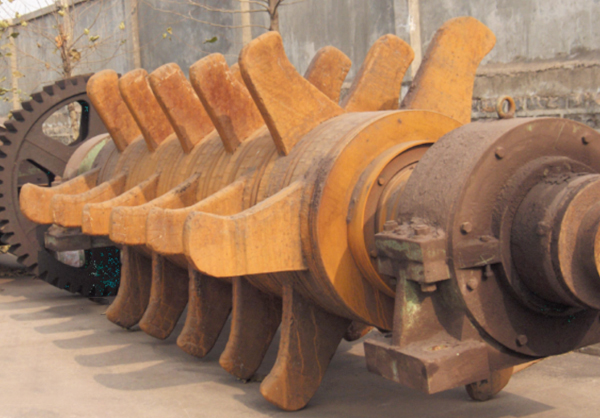

Double Tooth-roll Sinter CutterMain features of sinter cutter are excellent uniformity of product size, low fines content, low energy consumption and compact structure. ...

Double Tooth-roll Sinter CutterMain features of sinter cutter are excellent uniformity of product size, low fines content, low energy consumption and compact structure. ... -

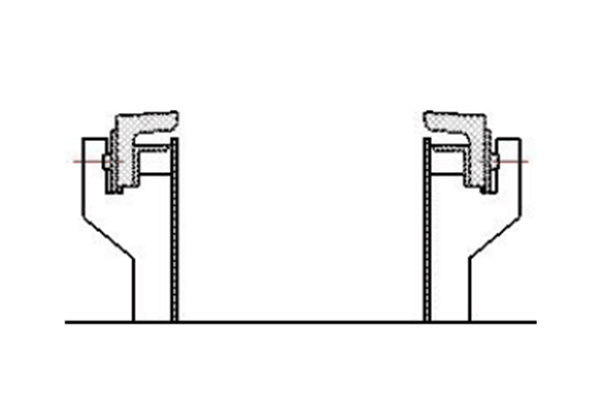

Double Roll SizerMain features: High throughput capacities up to 5000t/h at low operating cost Compact and flat design resulting in a low overall height of the crushing plant Low metallic wear and minimum fines content due to slow rotation speed of rotors Re...

Double Roll SizerMain features: High throughput capacities up to 5000t/h at low operating cost Compact and flat design resulting in a low overall height of the crushing plant Low metallic wear and minimum fines content due to slow rotation speed of rotors Re... -

Coke CutterANDE has developed CQJ series of tooth-plate coke cutter and CQD series of tooth-ring coke cutter (Patent no.: ZL 95 2 33983.8/ZL 2008 2 0024023.6), and about 400 sets have been in successful use in iron mills and coke-oven mills in China and ab...

Coke CutterANDE has developed CQJ series of tooth-plate coke cutter and CQD series of tooth-ring coke cutter (Patent no.: ZL 95 2 33983.8/ZL 2008 2 0024023.6), and about 400 sets have been in successful use in iron mills and coke-oven mills in China and ab... -

Impact CrusherImpact crusher is distinguished itself from others with the following advantages: High reduction ratio from 20 up to 150, leading to simple process flow by reducing crushing stages; Even size and cubical shape of final product owing to the i...

Impact CrusherImpact crusher is distinguished itself from others with the following advantages: High reduction ratio from 20 up to 150, leading to simple process flow by reducing crushing stages; Even size and cubical shape of final product owing to the i... -

HGGThe hot flue gas produced by burning fuel inside HGG shall be delivered into mixing room to mix with waste gas or circulating flue gas, and heat flue gas to the temperature of 220-380℃(adjustable according to the type of coal). Then the...

HGGThe hot flue gas produced by burning fuel inside HGG shall be delivered into mixing room to mix with waste gas or circulating flue gas, and heat flue gas to the temperature of 220-380℃(adjustable according to the type of coal). Then the... -

Barrel dryerThis dryer is mainly used for drying iron powder plus mixture on pellet production line in steel works. ...

Barrel dryerThis dryer is mainly used for drying iron powder plus mixture on pellet production line in steel works. ... -

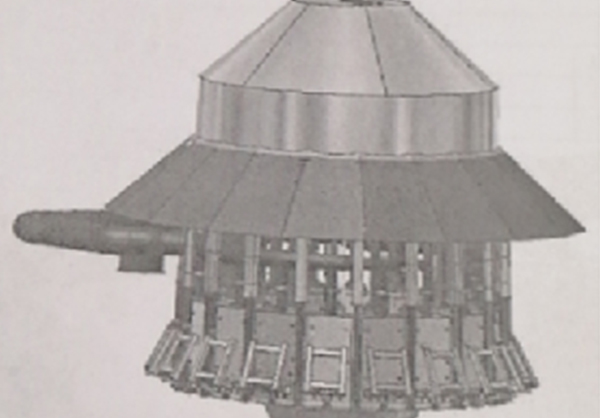

Balling discΦ6000 balling disc is used for pelletizing of iron ore fines. As one of main support equipment for various pellet plants, the equipment has strong adaptability, its inclination angle and rotation speed are adjustable, and the equipment adopts el...

Balling discΦ6000 balling disc is used for pelletizing of iron ore fines. As one of main support equipment for various pellet plants, the equipment has strong adaptability, its inclination angle and rotation speed are adjustable, and the equipment adopts el... -

Travelling grateThis machine is the dehydration equipment in the production line of oxidized pellet by grate-kiln method. Its function is to dry and dehydrate φ8-φ16mm ellipsoidal ball after rolling process. The working process of travelling grate is: sieve the...

Travelling grateThis machine is the dehydration equipment in the production line of oxidized pellet by grate-kiln method. Its function is to dry and dehydrate φ8-φ16mm ellipsoidal ball after rolling process. The working process of travelling grate is: sieve the... -

Rotary kilnThis rotary kiln is a kind of pellet kiln, the shell of which is made by steel plate rolling and welding. The inner diameter and length of kiln shell is 4.3m and 30m respectively. Inside the shell are lined with refractory bricks. The s...

Rotary kilnThis rotary kiln is a kind of pellet kiln, the shell of which is made by steel plate rolling and welding. The inner diameter and length of kiln shell is 4.3m and 30m respectively. Inside the shell are lined with refractory bricks. The s... -

Hermetic weighing feederTotally-enclosed weighing coal feeder is a kind of belt feeder with electronic measuring & weighing device, which is mainly applied to transfer coal from storage silo to coal mill. And it is equipped with speed sensor, coal interruption...

Hermetic weighing feederTotally-enclosed weighing coal feeder is a kind of belt feeder with electronic measuring & weighing device, which is mainly applied to transfer coal from storage silo to coal mill. And it is equipped with speed sensor, coal interruption... -

Bag filterMFseries bag filter is developed by our technical staff who draw lessons from domestic and abroad advanced dust collection technology, and it is widely applied in recycling and dust control in the fields of electric power, metallurgy, building ma...

Bag filterMFseries bag filter is developed by our technical staff who draw lessons from domestic and abroad advanced dust collection technology, and it is widely applied in recycling and dust control in the fields of electric power, metallurgy, building ma... -

Bin pumpAccording to technological process, XYB-s bin pump system is selected. The pump’s character is suit to transport the powder materials that is the big density, high moisture content. The bin pump’s control kernel is Simems-s PLC, and the control ...

Bin pumpAccording to technological process, XYB-s bin pump system is selected. The pump’s character is suit to transport the powder materials that is the big density, high moisture content. The bin pump’s control kernel is Simems-s PLC, and the control ... -

Annular coolerThis 30㎡ blast pellet annular cooling machine (hereafter referred to as annular cooling machine) is one of the major equipment in the production of metallurgical pellets. It is used in cooling the ~1150℃ pellets discharged from rotary kilns with...

Annular coolerThis 30㎡ blast pellet annular cooling machine (hereafter referred to as annular cooling machine) is one of the major equipment in the production of metallurgical pellets. It is used in cooling the ~1150℃ pellets discharged from rotary kilns with... -

Bell less topAdvantages of AS bell-less top Excellent process performance - Multifunction and accurate distribution can be achieved, such as single ring, multi ring, spiral, section, fixed positing; Simplified structure, reliable operat...

Bell less topAdvantages of AS bell-less top Excellent process performance - Multifunction and accurate distribution can be achieved, such as single ring, multi ring, spiral, section, fixed positing; Simplified structure, reliable operat... -

Rotary feederPulverized coal and granular coal injection system for BF Pulverized coal injection system for rotary kiln and shaft kiln Iron ore powder, pulverized coal and flux injection system in direct reduction ironmaking process Injecti...

Rotary feederPulverized coal and granular coal injection system for BF Pulverized coal injection system for rotary kiln and shaft kiln Iron ore powder, pulverized coal and flux injection system in direct reduction ironmaking process Injecti... -

Dome valveDome Valve is material conveying valve which is the most effective and fast-opening material conveying valves in the world. They are specially used in pneumatic conveying systems. Their industrial applications include power, food, medicine, chem...

Dome valveDome Valve is material conveying valve which is the most effective and fast-opening material conveying valves in the world. They are specially used in pneumatic conveying systems. Their industrial applications include power, food, medicine, chem... -

Vertical preheateMain function of shaft preheater is that qualified limestone is sent to main body of preheater to exchange heat with counter flow high-temperature flue gas (about 1150℃) discharged from rotary kiln after calcination. ...

Vertical preheateMain function of shaft preheater is that qualified limestone is sent to main body of preheater to exchange heat with counter flow high-temperature flue gas (about 1150℃) discharged from rotary kiln after calcination. ... -

Vertical coolerCalcined lime inside rotary kiln enters into the shaft cooler main body through kiln and grate bar device in sequence. Kiln head hood and inner wall of shaft cooler are lined with refractory materials. Cross section of shaft cooler is square. ...

Vertical coolerCalcined lime inside rotary kiln enters into the shaft cooler main body through kiln and grate bar device in sequence. Kiln head hood and inner wall of shaft cooler are lined with refractory materials. Cross section of shaft cooler is square. ... -

Rotary feederPulverized coal and granular coal injection system for BF Pulverized coal injection system for rotary kiln and shaft kiln Iron ore powder, pulverized coal and flux injection system in direct reduction ironmaking process Injecti...

Rotary feederPulverized coal and granular coal injection system for BF Pulverized coal injection system for rotary kiln and shaft kiln Iron ore powder, pulverized coal and flux injection system in direct reduction ironmaking process Injecti...

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube