Single-roll crusher is applied for crushing of fragile and low/medium-hardness material, such as sinter, slag, shale, limestone and etc..

Single roll crusher integrates jaw crusher and roll crusher together, thus has characteristics of the two types of crushers.

One rotating toothed roll and a set of grate bars constitute broken mechanism of single-roll crusher. Crushing roll is driven by e-motor through reducer. Material lumps enter between crushing roll and grate bars via charging plates, and then crushed with squeezing and breaking by toothed roll and grate bars. To enhance stability and wear-resistance at high temperature, water circulating system is equipped to cool crushing roll shaft, crushing teeth and grate bars.

-

Drive mode

E-motor drives tooth roll through safety coupling/ fluid coupling and reducer with big reduction ratio.

E-motor drives tooth roll through safety coupling, reducer with small reduction ration and open gear set.

-

Fixed base frame/Mobile trolley

Grates are placed on base frame, and crushing roll and base frame are fixed on concrete base. Structure is compact and it is easy to install.

Bearing brackets of crushing roll are fixed on the foundation, and grates are placed in the trolley, under which there are wheels and rails. While working, trolley is fixed firmly on the base. When repairing grates, trolley can be moved down to paved rails and pulled out by winch unit for maintenance.

-

Bearing

PSB alloy bearing shell or roller ball bearing is adopted to meet requirement of poor working conditions, heavy load, low speed. Bearing box is split type.

-

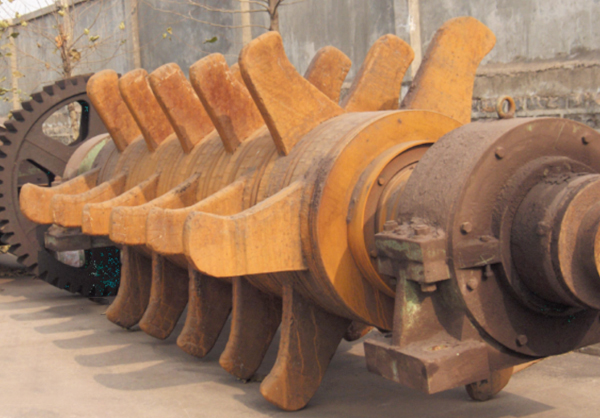

Crushing roll

Star wheels and main shaft of crushing roll are made separately. Star wheels and main shaft are of inside and outer hexagonal design for easy replacement. Main shaft is drilled with through-hole for cooling with circulating water. There are two types of crushing teeth:

Made of heat-resistance & wear-resistance alloy steel, and mounted on star wheels.

Cast with star wheel as a whole with crushing section hard faced with heat & wear-resistance welding wire.

-

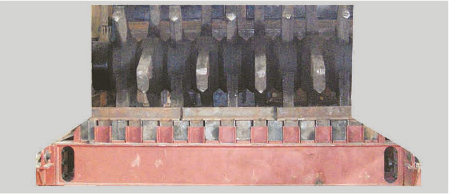

Grate

Grate is fitted with liner, made of heat & wear-resistance alloy steel.

Surface of grate is hard faced with heat & wear-resistance welding wire.

|

Model No. |

Output(t/h)

|

Feed size(mm)

|

Product size(mm)

|

Motor power(kw)

|

|

DGP85 |

40-50 |

≤250×400×1000 |

≤90 |

22 |

|

DGP1116 |

70-80 |

≤300×500×1400 |

≤100 |

30 |

|

DGP1118 |

80-90 |

300×500×1500 |

≤100 |

37 |

|

DGP1521 |

140-160 |

≤500×1000×2000 |

≤150 |

45 |

|

DGP1524 |

180-200 |

≤500×1000×2200 |

≤150 |

55 |

|

DGP1527 |

220-240 |

≤500×1000×2500 |

≤150 |

75 |

|

DGP1628 |

230-250 |

≤500×1100×2500 |

≤160 |

75 |

|

DGP1832 |

420-450 |

≤500×1100×3000 |

≤180 |

90 |

|

DGP2042 |

550-600 |

≤500×1100×4000 |

≤200 |

110 |

|

DGP2248 |

800-900 |

≤500×1100×4500 |

≤200 |

132 |

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube