Coke cutter is developed based on analysis of coke physical property and application of up-to-date crushing technique. It makes the working mechanism more reasonable by replacing crushing with splitting and cutting. Consequently the ratio of fine coke is reduced by over 10% compared with normal double-roll crusher. Reliable drive system is adopted to guarantee tooth rolls to operate smoothly and consume less energy.

ANDE has developed CQJ series of tooth-plate coke cutter and CQD series of tooth-ring coke cutter (Patent no.: ZL 95 2 33983.8/ZL 2008 2 0024023.6), and about 400 sets have been in successful use in iron mills and coke-oven mills in China and abroad.

With wide application of Pulverized Coal injection (PCI) technology, coke, as the supporting frame in blast furnace, is playing a more important role, leading to higher demand on strength, uniformity and hot state strength. Usually coke sized over 75mm has loose structure and more primary crack. The broken coke resulting from feeding and falling in blast furnace will directly affect permeability of stock column. Sizing process has coke to be worn and broken before entering blast furnace. It improves not only size uniformity apparently but also mechanical strength (M40) and hot state strength to some extent, and then becomes an important measure for steady and high output of blast furnace.

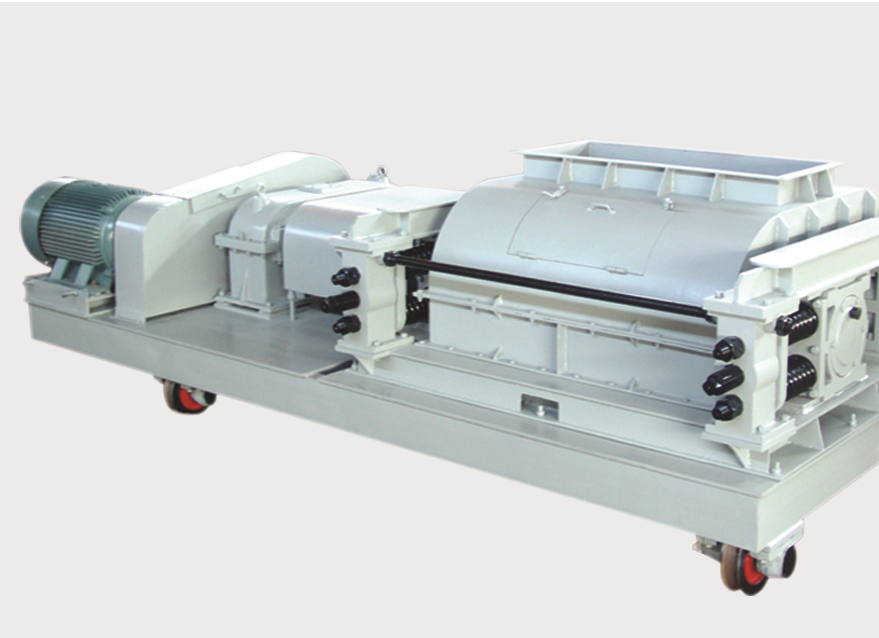

The material is fed into the machine by means of belt-conveyors or vibrating feeders while it is spread over the whole length of the roll. The crushing rolls are driven in counter-rotation by a single electric motor, which guarantees rolls to rotate constantly at differential rotation velocity (rotation velocity ratio=1:2) . The material is cut and split by long alternating with short axe-blade teeth on the rolls. In order to alter the gap width to compensate wear and tear of teeth, one of rolls is designed as a loose roll. Output depends on roller diameter and length, rotation velocity and gap width. Product size is mainly decided by gap width, tooth width and tooth length.

Compared with normal double roll crusher through crushing and extruding, coke cutter is much more effective:

Product size is more uniform: coke sized 25-80mm accounts for over 80%, much higher than double roll crusher.

Fine coke is minimized: the ratio of fine coke is above 10% lower than that of double roll crusher, and then the coke utilization ratio is increased remarkably.

-

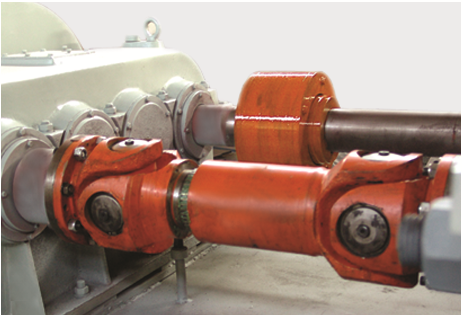

Drive unit

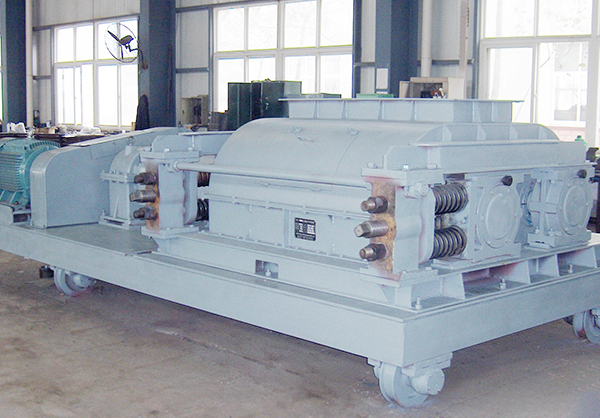

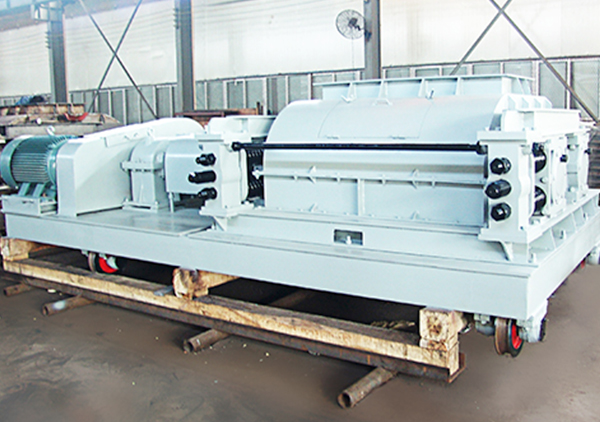

The drive system of CQD series of coke cutter adopts a reducer with double output shaft coupled with universal coupling and ball coupling. The reducer is sealed well and works reliably. Tooth roll is composed of roller shaft and columns of round tooth rings. As the roll assembly can be easily replaced, time spent in replacing wear parts (tooth rings) on site can be reduced greatly. All assembly are fixed on a whole base frame to facilitate mounting on site.

-

Moving wheels

Moving wheels are arranged below the welded base frame of the machine to facilitate maintenance.

-

Tooth roll

For gap adjustment and overload protection of rolls, the spring cushion unit or hydraulic unit is adopted.

As wearing part, the tooth ring or plate is made of high manganese or Mn-Cr alloy casting in order to achieve long lifetime.

-

Electro-magnetic iron-remover

An electro-magnetic iron-remover has to be hanged over belt conveyors to assure the machine running continuously and safely.

|

Model No. |

Type of crushing tooth |

Output(t/h) |

Feed size(mm)

|

Product size(mm) |

Motor power(kw) |

|

CQJ-60 |

Tooth plate |

25 |

≤200 |

≤50 |

15 |

|

CQJ-60T |

Tooth plate |

10 |

≤80 |

≤25 |

18.5 |

|

CQJ-70 |

Tooth plate |

40 |

≤200 |

≤50 |

18.5 |

|

CQJ-70T |

Tooth plate |

20 |

≤80 |

≤25 |

22 |

|

CQJ-80 |

Tooth plate |

60 |

≤300 |

≤70 |

22 |

|

CQJ-80T |

Tooth plate |

30 |

≤100 |

≤30 |

30 |

|

CQJ-90 |

Tooth plate |

90 |

≤300 |

≤70 |

37 |

|

CQJ-90T |

Tooth plate |

35 |

≤100 |

≤30 |

37 |

|

CQD-70 |

Tooth ring |

75 |

≤350 |

≤70 |

22 |

|

CQD-70T |

Tooth ring |

40 |

≤100 |

≤30 |

37 |

|

CQD-80 |

Tooth ring |

110 |

≤350 |

≤70 |

30 |

|

CQD-80T |

Tooth ring |

60 |

≤100 |

≤30 |

45 |

|

CQD-90 |

Tooth ring |

160 |

≤350 |

≤70 |

45 |

|

CQD-90T |

Tooth ring |

80 |

≤100 |

≤30 |

55 |

|

CQD-100 |

Tooth ring |

200 |

≤400 |

≤70 |

55 |

|

CQD-110 |

Tooth ring |

300 |

≤400 |

≤70 |

75 |

|

CQD-120 |

Tooth ring |

450 |

≤400 |

≤70 |

90 |

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube