Impact crusher is particularly used for primary and secondary crushing of medium /low-hardness material, whose compressive strength is up to 250MPa, such as raw gypsum, hard coal, limestone, shale, petrocoke and etc. for mining and pit and quarry industries.

Impact crusher is distinguished itself from others with the following advantages:

High reduction ratio from 20 up to 150, leading to simple process flow by reducing crushing stages;

Even size and cubical shape of final product owing to the increased number of crushing chamber;

High capacity and large feed size, resulting from bigger crushing chamber and higher rotor speed;

Low operating cost due to the low energy consumption and metallic wear.

After entering the crushing chamber of impact crusher, the feed material is struck by the high-velocity plate hammers on the rotor, and the crushed material is flying off at a tangent against the breaker plates at the other end of the crushing chamber to be crushed again. Then it is rebound to plate hammers and the above course continues repeatedly. With strike by plate hammers, impact with breaker plates and inter-collision, the material is keeping cracked and smashed. While the particle size is smaller than the gap between breaker plate and plate hammer, the sized material is discharged out of the impact crusher.

-

Drive unit

There are two options: belt drive and direct drive. When the driving power is high, a direct drive with fluid coupling is preferred.

-

Rotor

The rotor of ANDE impact crusher is characterized by large-diameter and robust fabricated steel cast, which guarantee high inertia required for reliable crushing performance. The rotor is further strengthened with a chrome alloy forged shaft. In some cases a double-rotor impact crusher is employed as series application of two crushers for high reduction ratio and simple process flow.

-

Hammer

The mass and banana shape are critical to the design of plate hammer, leading to more effective shearing and collision of feeding material and thus improved production. With the two-edge design, the plate hammer can be turned round to maximize use life. The heavy duty backing plates and hammer lock wedges stably hold plate hammers both vertically and horizontally by giving solid abutment positioning and maintaining rigidity during operation.

-

Curtain

According to the product size, 2 or 3 heavy curtains are provided inside the housing to form the crushing chamber. Mounted on pivoting shaft, each of them is separately adjustable. The curtain is furbished with wear liners, made of high manganese alloy steel cast with modular design.

-

Curtain adjustment mechanism

The gap between rotor and curtain can be adjusted to optimize performance. Presently the electrically operated hydraulic system makes the adjustment as well as frame opening much easier.

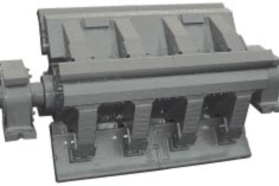

Impact crusher mainly consists of drive unit, rotor, curtain, adustment mechanism and housing.

|

Type No. |

PF-1013 |

PF-1214 |

PF-1315 |

PF-1320 |

|

Rotor diameter(mm) |

1000 |

1250 |

1300 |

1300 |

|

Rotor width(mm) |

1300 |

1400 |

1500 |

2000 |

|

Feed size(mm) |

250 |

300 |

350 |

350 |

|

Capacity(t/h) |

50-120 |

80-180 |

100-250 |

200-350 |

|

Power(kw) |

110-185 |

132-200 |

180-315 |

300-400 |

|

Type No. |

PF-1622 |

PF-1822 |

PF-1638 |

PF-1838 |

|

Rotor diameter(mm) |

1600 |

1800 |

1600 |

1800 |

|

Rotor width(mm) |

2200 |

2200 |

3800 |

3800 |

|

Feed size(mm) |

400 |

500 |

800 |

1000 |

|

Capacity(t/h) |

400-600 |

500-800 |

800-1000 |

1000-1200 |

|

Power(kw) |

450-560 |

560-710 |

850-1120 |

950-1250 |

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube