1 Overview

Limestone pulverizing system is main section of desulfurizer preparation in power plant. With desulfurized lime mill as the core, dry grinding is adopted, and the particle size is adjusted by dynamic separator. The system can achieve various particle sizes of 0.1-0.5mm, 0.074mm and 0.044mm, which is suitable for the preparation of various desulfurizer.

2 Main charateristic

New type of vertical roller mill system is used in grinding, which has the advantages of high grinding efficiency, large single machine capacity, low return rate, low power consumption, low metal wear, low noise and small maintenance workload.

Vertical mill integrates grinding, drying and sorting into one. High concentration bag collector is used to collect the powder. The technological process is simple, the number of equipment is small and the fault points are few.

Process layout is compact, the area of the system is small, and the cost of the workshop is low.

System adopts negative pressure operation, no dust leakage and friendly working environment.

Production operation can be adjusted flexibly, and the output and product fineness can be adjusted online in real time.

Production is stable and reliable.

In consideration of the wear resistance of the parts in contact with materials in limestone pulverizing system, HARDOX lining plate is selected for chute and silo lining, wear-resistant ceramic plug valve is used for valve, and ceramic lining is used for elbow.

Fully reflect the design concept of low energy consumption and low operation cost, such as the main induced draft fan uses high-voltage frequency conversion technology to adjust the air volume and air pressure, and power supply system adopts reactive power compensation to reduce line loss and save electric energy.

Automatic control is practical and reliable.

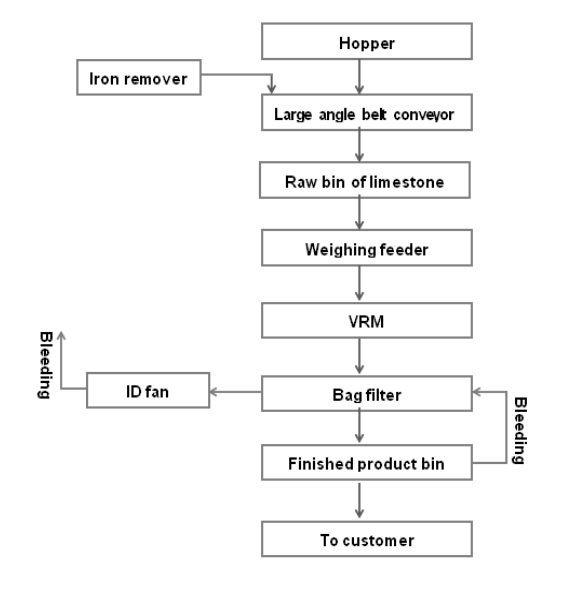

3 Technical process

Limestone is fed into hopper by loader and transported to the raw material bin by belt conveyor with a large inclination angle. A sealed weighing feeder is set under the bin to feed the raw materials to the vertical mill in a uniform and quantitative manner. The qualified powder discharged from the mill enters into the bag type powder collector for powder collection under the action of the main induced draft fan, and the collected fine powder is discharged into the finished product bin.

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube